on the latest virtual assembly of SmartX, the eu sensible Textiles Accelerator, on October 9th, the versatility of flat knitting and the productiveness of embroidery in the introduction and commercialisation of new sensible fabrics were emphasised.

SmartX has just made its closing call for challenge applications, with businesses having unless February fifteenth to at ease as much as €60,000 in funding every.

This follows the a hit 2nd name, which opened in June 2020 and changed into met with a high stage of hobby from the cloth and know-how industries, regardless of the continuing Covid-19 pandemic. The call resulted in 29 achieved purposes,19 of which were submitted through consortia. In total, 56 SMEs from sixteen different european and linked countries utilized. Most proposals addressed well being markets, whereas the rest concentrated on fitness and insurance plan.

Backed through the eu Union's Horizon 2020 analysis and innovation scheme, the three-year SmartX Europe programme is supporting as much as forty wise material initiatives with a total price range of €2.4 million and also providing a 12 months of free teaching to help beginning-united states of americaand small agencies increase their technologies and set up the contacts they need.

"After identifying 20 tasks worth over €1.5 million all through our first two SmartX calls, we are actually hunting for our third and last cohort of trailblazer initiatives ready to overcome pleasing market niches in the insurance plan, sports, fitness and industrial conclusion markets with disruptive smart cloth options." mentioned Lutz Walter, secretary regularly occurring of cloth ETP, a SmartX companion and the programme coordinator. The acceleration platform is pushed through a consortium of 13 European companions from the textile and know-how industries.

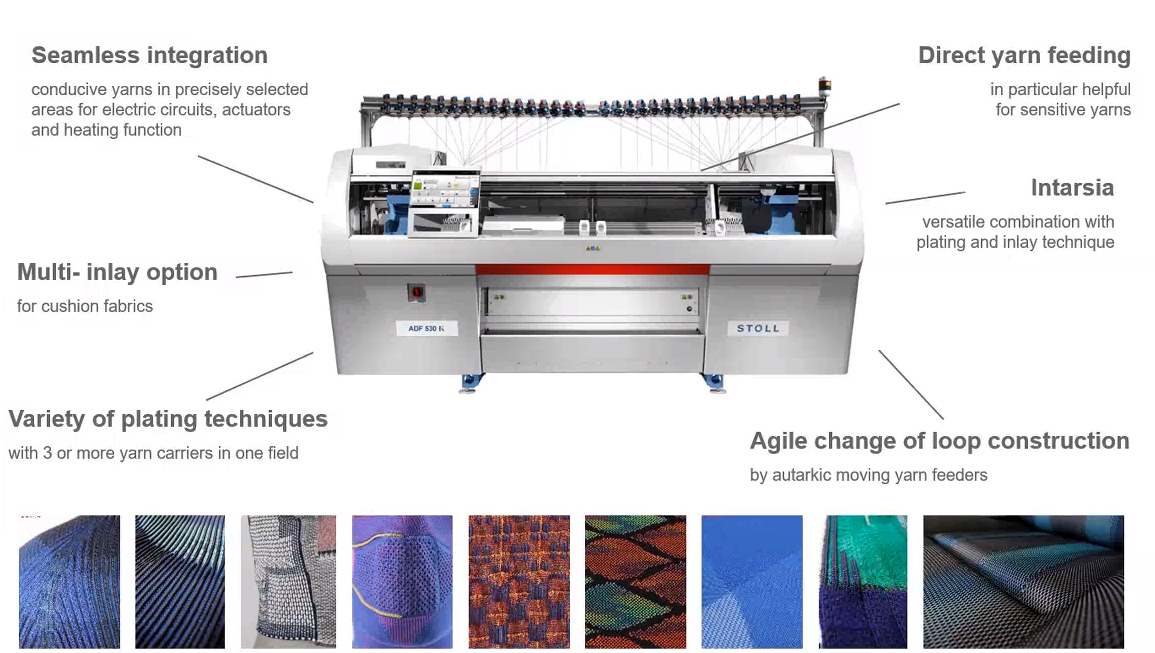

Stoll ADF

Alexander Behm, Stoll's technical textiles product supervisor, explained how limitless new sensible cloth designs are viable on the enterprise's ADF flat knitting computing device, by way of intarsia, plating and interlaying thoughts for specifically integrating functional silver-coated polyamide or pure chrome steel or copper yarns to create flexible conductors for heating aspects, sensors and actuators.

Many alternate options have already been realised via Stoll's partnership with Myant, and other business examples include the heated garments marketed by way of Germany's WarmX.

A existing medical software made with the Stoll gadget is a knitted gold mesh employed as an electrode within a device for the transfer of radio frequency (RF) energy within the remedy of menstrual ache.

possibly probably the most refined product created so far on the Stoll equipment, besides the fact that children, is the glove created for Robert Bosch – Europe's greatest company of car accessories, with 2019 sales of €77.7 billion.

This seamless, 3D flat-knitted glove is fabricated from yarn sensors which permit the wearer to experience and handle functions in man-laptop interactions.

An intarsia plating technique changed into employed to create the glove's conductive and flexible sensors at the tip of each and every finger and a selective plating method allowed the 12 electric paths, each in accordance with single yarn feeders, to be precisely placed.

"Sensors were built-in in a tubular structure and we employed elastic yarns to supply consolation to the glove's customised shape," Behm noted. "The glove retains full breathability, despite its complicated design."

ZSK multi-heads

Melanie Hoerr, supervisor of technical embroidery for ZSK, based in Krefeld, Germany, defined that for the introduction of wise fabric, three of the enterprise's separate embroidery heads can also be mixed in a single machine:

- The F-Head, which is the most frequent for decorative embroidery and has been employed to mass produce sensible fabrics in accordance with yarns containing LEDs and RFID chips linked to a PCB (printed circuit board), which is first fixed to the textile substrate, followed through conductive paths being embroidered from it to the particular person sensor areas.

- The k-Head for the realisation of tailor-made patterns with 3D shapes inbuilt loops on true of the base fabric – so-known as moss embroidery' – to create very first rate conductive areas for reading biosignals by way of 'dry' sensors. Moss-embroidered cloth sensors obtain lots nearer contact with the physique in a must-have-signals size for clearer and more positive indicators. "This makes it feasible to believe the sensor without seeing it," Hoerr pointed out.

- The okay-Head, for tailor-made wire placements as heating aspects, electro-luminescence, RFID antennas in any shape. A video turned into shown of a sequence of eleven such heads inserting full heating facets into motor vehicle seat pads at a price of 2,000 per 24 hours operation.

ElectroSkin

Daniela, Zavec of the smart textiles consultancy Titeria, extra outlined how one company she has worked with, Nanoleq in Switzerland, is making the advent of smart fabric for biosensing and different purposes totally purchasable to new entrants to the field.

Nanoleq has developed key add-ons that can be with no trouble applied to garments via sizzling press lamination.

"Importantly, Nanoleq has developed no longer simply the add-ons but the finished trying out protocol in terms of washability, stretch reststance, chemical resistance and other efficiency attributes, to make sure the robstness of recent products in accordance with these add-ons," Zavec referred to.

Nanoleq claims its ElectroSkin electrodes are light, skinny and their skin impedance is even more suitable than average clinical gel electrodes, devoid of wetting and even after repeated washing.

A starter kit including 12 of the ElectroSkin electrodes, insulation patches for connections, conductive snap buttons and assisting tools, a laminated reference sample and SOP documentation is currently attainable from the company priced at €880, together with 90 minutes of mobilephone guide for laminating and connecting issues.

could developing new sensible fabrics be any more convenient?

That closing demand SmartX challenge applications is open until 15 February.

No comments:

Post a Comment