As a metal platform rises from a vat of liquid resin, it pulls an difficult white form from the liquid — like a waxy creature rising from a lagoon. This machine is the world's fastest resin-based 3D printer and it might create a plastic structure as giant as someone in a number of hours, says Chad Mirkin, a chemist at Northwestern college in Evanston, Illinois. The laptop, which Mirkin and his colleagues suggested closing October1, is considered one of a slew of analysis advances in 3D printing which are broadening the possibilities of a expertise once seen as helpful chiefly for making small, low-high-quality prototype elements. now not simplest is 3D printing becoming quicker and producing better items, however scientists are arising with imaginitive tips on how to print and are developing improved materials, on occasion mixing varied substances within the same product.

sportswear businesses, aviation and aerospace manufacturers and medical-device groups are desperate to take abilities. "You're now not going to be sitting to your home, printing out exactly what you need to repair your automobile any time quickly, but important manufacturing businesses are really adopting this technology," says Jennifer Lewis, a substances scientist at Harvard institution in Cambridge, Massachusetts.

The latest techniques may be profitable for researchers, lots of whom — Lewis and Mirkin amongst them — are already commercializing their work. They're additionally fundamentally exciting, says Iain Todd, a metallurgist at the university of Sheffield, UK. "we can get performance out of those substances that we didn't feel we may get. That's what's basically wonderful to a materials scientist. here is getting individuals used to the brand new bizarre."

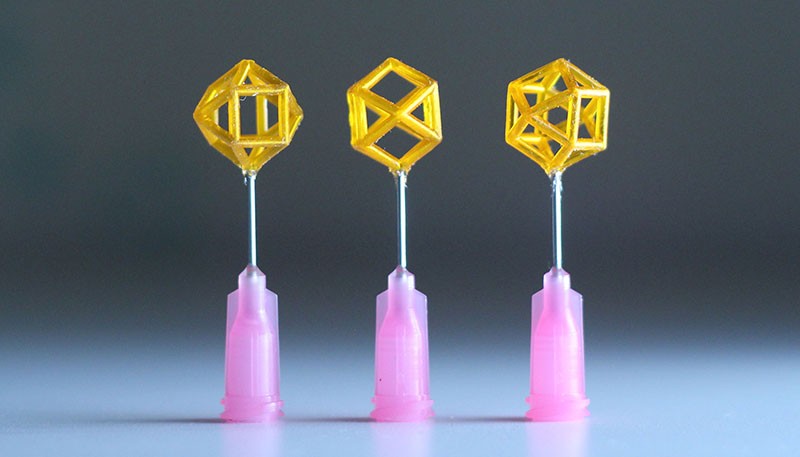

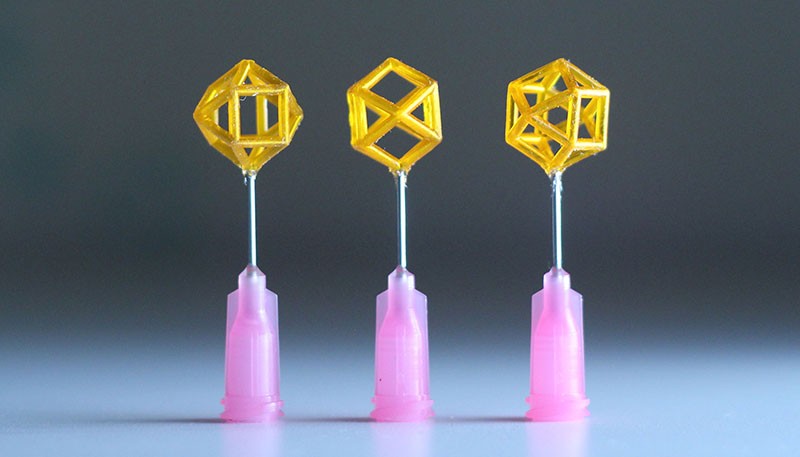

From trinkets to itemsThe 3D printing technique is often known as 'additive manufacturing', as a result of as an alternative of slicing or milling a shape out of a bigger block, or casting molten cloth in a mould, it contains constructing objects from the backside up. Its advantages encompass much less waste and an ability to print custom designs, similar to complex lattice structures, which are in any other case tough to create. reasonably priced hobbyist machines print with the aid of squeezing out thin plastic filaments from heated nozzles, build up a structure layer by way of layer — a method known as fused deposition modelling (FDM). but the time period 3D printing incorporates a a good deal wider range of options. one of the crucial oldest makes use of an ultraviolet laser to scan across and solidify (or 'remedy') light-delicate resin, layer with the aid of layer. That idea was described as far back as 1984, in a patent filed through Charles Hull2, the founding father of a company known as 3D methods in Rock Hill, South Carolina.

The latest suggestions — together with Mirkin's — still use mild-delicate resin, however are faster and bigger-scale, following improvements mentioned in 2015 by way of a group led via Joseph DeSimone, a chemist and substances scientist at the tuition of North Carolina at Chapel Hill3. Early printers had been sluggish, small-scale and prone to producing layered, imperfect and weak buildings. These found a gap in rapid prototyping, making plastic model components as mock-usafor later construction through established methods. As a local of research, this type of printing wasn't interesting, says Timothy Scott, a polymer scientist at Monash school in Melbourne, Australia: "definitely making trinkets and knick-knacks. For a polymer chemist, it become relatively stupid."

In 2015, Joseph DeSimone on the university of North Carolina at Chapel Hill unveiled a method to pace up 3D printing.credit score: Carbon 3D Inc.

Then DeSimone unveiled a method to print gentle-sensitive resin as much as a hundred times sooner than customary printers3. It makes use of a stage submerged in a vat of resin. A digital projector shines a pre-programmed photograph up at the stage through a clear window within the ground of the vat. The gentle remedies a whole resin layer directly. DeSimone's develop become to make the window permeable to oxygen. This kills the curing reaction and creates a thin buffer layer, or 'dead zone', just above the window's floor so that the resin doesn't sti ck to the bottom of the vat each and every time a layer is printed. The stage rises continuously, pulling the accomplished half up during the liquid as new layers are delivered at the bottom.

different labs were working on similar ideas at the time, says Lewis. but possibly most magnificent about DeSimone's resins was that they may endure a 2nd response in a put up-print heat remedy to improve the accomplished product. "It opens up a a good deal broader array of substances," says Lewis.

Many analysis groups and businesses have in view that constructed on the work. Mirkin's printer pumps a layer of clear oil throughout the bottom of the vat to inhibit the polymer's reactions. This additionally acts as a coolant, casting off heat that may deform a published half — and it capacity that the device is not restricted to printing with resins that are inhibited by means of oxygen. He says the printer produces fabric ten times quicker than DeSimone's. And remaining January, Scott and his colleague Mark Burns on the college of Michigan in Ann Arbor reported a printer that inhibits the reactions by means of mixing into the resin a chemical that will also be activated by using a second lamp emitting a special wavelength of mildfour. via varying the ratio of the strength of the two gentle sources, the researchers can handle the thickness of the photograph-inhibited zone, permitting the advent of extra advanced patterns, similar to surfaces embossed with seals or trademarks.

inventions in 3D printing commonly have rapid commercial competencies: some researchers beginning forming businesses earlier than they post their advances. On the identical day DeSimone's paper turned into posted, for instance, he showcased it at a TED speak in Vancouver, Canada, and formally launched his birth-up firm Carbon 3D in Redwood metropolis, California, however he had quietly registered the enterprise two years earlier. The firm is now one of the most greatest birth-u.s.a.in 3D printing; it has already raised US$680 million in publicly disclosed funding rounds, and is reportedly valued at $2.4 billion. It has high-profile contracts with Adidas to make rubber-like midsoles for athletic shoes, and with sports-gea r firm Riddell to fabricate personalized helmet padding for American-soccer players.

Carbon 3D's know-how is used to print Adidas shoes (left) and padding for American soccer helmets (correct).credit score: Carbon 3D Inc.

Mirkin and his colleagues James Hedrick and David Walker have also launched a beginning-up, Azul 3D in Evanston, Illinois, to commercialize their technique, which they've dubbed HARP (high-area swift printing). And Scott and Burns are getting ready a industrial prototype printer with their Ann Arbor-based mostly start-up Diplodocal, a reputation derived from the Greek for 'double beam'.

New resin-printing options are nonetheless rising. One begins with a small spinning glass keeping liquid resin. because the glass rotates, a projector shines a loop of video onto it that corresponds to 2d slices of the preferred object. inside seconds, the closing object solidifies inside the liquid resin — no layers crucial5. The formulation is impressed by way of X-rays and computed-tomography scans, which graphic a move-portion of a solid object. here's the inverse: returned-projecting go-sections to form a 3D object.

A projector shines a video loop onto liquid resin, inflicting an entire object to be created without delay, rather than layer by means of layer.credit: UC Berkeley

Even in this quick-relocating container, the method became heads for what Lewis calls "the gee-whiz ingredient". It has gigantic limitations: the resin used ought to be transparent, and the printed object should be small satisfactory for easy to flow via it to remedy it. however it additionally has a potential expertise: it might tackle particularly viscous resins, which different resin-based printers fight to suck during the slim dead zone. That skill it could make more advantageous materials and greater accurate prints.

The method has garnered sizeable hobby from industry, says Christopher Spadaccini, a materials and manufacturing engineer at Lawrence Livermore countrywide Laboratory (LLNL) in California. Spadaccini was a member of the crew that posted the work last January5. a group on the Swiss Federal Institute of technology in Lausanne (EPFL) independently developed the same thought, and has additionally pronounced a demonstration of it6. Spadaccini thinks the technology has big business talents because it has modest hardware necessities. "within the end, basically, what you want is a halfway-decen t projector and a rotating stage," he says.

Going massivewhile chemists work on smarter ways to 3D-print intricate resins, engineers are pushing boundaries in 3D printing of concrete — the usage of computers and robots to precisely automate the pouring system.

A 3D-printed concrete pedestrian bridge developed by Tsinghua institution.credit: Imaginechina/Shutterstock

the world's first 3D-printed concrete pedestrian bridge changed into made by researchers at the Institute for superior structure of Catalonia in Barcelona, Spain, and installed in a park in Alcobendas, near Madrid, in 2016. Twelve metres lengthy, the bridge points a lattice structure designed with algorithms that maximize strength and reduce the amount of cloth crucial. other teams have made identical constructions, together with a 26-metre-lengthy bridge in Shanghai, China, produced by means of engineers at Tsinghua university in Beijing. And teams and agencies in China and the Netherlands have 3D printed demonstration residences.

those structures aren't developed in one print job, however: separate segments are printed and then linked. by means of producing bridges and properties more cheaply and successfully, 3D printing might reduce concrete's carbon footprint — however may additionally simply motivate engineers to construct extra.

It's now not just concrete that is going large: Amsterdam firm MX3D has printed a bridge from chrome steel. First displayed publicly in 2018, the bridge is now being validated and having sensors put in forward of a planned setting up over an Amsterdam canal.

A view of MX3D's printer all the way through the procedure of printing a metal bridge.credit score: Olivier de Gruijter/MX3D

And California beginning-up enterprise Relativity house in la says it's constructing an almost utterly 3D-printed rocket. The rocket is designed to raise 1,250 kilograms into low Earth orbit, and its first verify launch is slated for 2021. Printed metallic doesn't always have the identical warmth-dissipating performance as non-printed metallic, says Relativity house's chief government, Tim Ellis, however the printing procedure can add cooling channels in geometries that can't always be manufactured. because rockets are used only once or perhaps a few instances, they don't need to be as robust in the long run as do alloys in aeroplane elements, which need to resist failure over tens of thousands of drive cycles, Ellis says.

A metallic printer at start-up firm Relativity area, which goals to check a by and large 3D-printed rocket in 2021.credit score: Relativity house

These big-scale metal-printed initiatives are developed with robotic fingers that feed a thin metallic wire to a laser that welds the fabric into area. other centered methods to print steel use a laser or a beam of electrons to melt or fuse a bed of powder into layers of complete product. an additional technique binds a bed of powder with liquid glue, then sinters the structure in a furnace. And printers designed during the past few years extrude molten metals via nozzles, in a great deal the equal manner as in FDM.

Aviation enterprises comparable to Boeing, Rolls Royce and Pratt & Whitney are using 3D printing to make metal elements, above all for jet engines. It will also be more cost-effective than milling steel blocks, and the complicated accessories often weigh less than their conventionally made counterparts.

however 3D-printed metals are prone to defects that can weaken the last items. Spadaccini and others are trying to make use of arrays of sensors and excessive-velocity cameras to look ahead to irregularities corresponding to hotspots of heat or stress — and then make adjustments in true time, he says.

Many scientists are additionally hoping to improve the intrinsic strength of printed metals, every so often via controlling the microstructures of the substances. as an instance, in October 2017, a US crew said that the severe warmth and fast cooling used in 3D-printing chrome steel may alter the steel's microstructure such that the product is improved than those forged conventionally7. And two months in the past, researchers in Australia and the USA reported a titanium–copper alloy with an identical power advantageseight. As they solidified, old 3D-printed titanium alloys tended to f orm grains that grew in column-like constructions. The copper helps to speed up the solidification system, which outcomes in grains that are smaller and sprout in all instructions, strengthening the typical structure.

Mark Easton, a substances engineer at RMIT school in Melbourne and one of the leaders of the alloy work, has already had conversations with aerospace groups interested in exploring uses for the material. He says it might even be used in medical implants reminiscent of joint replacements.

many of the printing thoughts that work for metals can also be applied to ceramics, with advantage purposes that consist of making dental crowns or orthopaedic implants. Moulds for these objects are already made by way of 3D printing, with the material solid in the standard means. however 3D-printing the whole object may save time at the dentist or surgeon's office.

despite the fact, it's tougher to control the microstructure of 3D-printed ceramics, says Eduardo Saiz, a substances scientist and ceramicist at Imperial college London. And almost all purposeful ceramic printing strategies contain huge post-print sintering that can warp or deform the part. "personally, ceramics is way behind polymers and metals in terms of useful functions," he says.

alternate over timeThe field's future might also lie in '4D printing' — 3D-printed objects that even have the ability to operate some mechanical action, equivalent to synthetic muscle mass. often, these contain shape-reminiscence polymers, materials that may react to changes of their environment similar to warmth or moisture.

In may also 2018, researchers at the Swiss Federal Institute of know-how (ETH) in Zurich and the California Institute of know-how in Pasadena pronounced printing a submarine that propels itself forward the usage of paddles that snap backwards when placed in warm water9. The work may lead to microrobots that may explore the oceans autonomously. however for the second, the paddles have to be reset after every stroke. Such devices might use battery power to reset themselves, however that makes the laptop less productive than one made conventionally, says Geoff Spinks, a substances engineer on the school of Wollongong in Australia. "There are nonetheless some massive challenges with 4D printing," he says.

an additional approach to 4D-printed gadgets contains triggering the action with a altering external magnetic box. US researchers have 3D-printed lattice structures crammed with a liquid that adjustments stiffness in line with a magnetic container10 — which may perhaps be used to support car seats stiffen on impact.

A fluid that stiffens in line with a magnetic container is injected into the hole struts and beams of a 3D-printed lattice. The cloth can also be made stiff or flexible.credit score: Julie Mancini/LLNL

other, extra passive potential 4D printing applications include stents, which may be compressed to be implanted then expanded on accomplishing the favored web site in a blood vessel to prop it open. ultimate July, researchers in Switzerland and Italy described a 4D-printed stent that is barely 50 micrometres wide11, lots smaller than accepted ones. The instruments are so small, the crew says, they might someday be used to deal with complications in fetuses, such as strictures in the urinary tract, that may from time to time be fatal.

possibly probably the most bold instance of 4D printing is remember that not most effective moves, but is alive. at the moment, innovations for such bioprinting can print tissue, equivalent to human skin, that's appropriate for lab analysis, in addition to patches of tissue for livers and other organs that have been successfully implanted in rats. however such innovations are nevertheless removed from ready to combine right into a human physique. Researchers dream of printing wholly functioning organs that might alleviate lengthy wait lists for organ donors. "I in my view feel we're a decade-plus away from that, at least, if ever," says Lewis.

All together nowMany inventive ideas about printing be counted that moves or alterations depend on printing numerous materials together. "That's fully where the box is heading," says Scott.

closing November, Lewis and her lab described a printer that can swiftly switch between distinct polymer inks or mix them because it prints a single object12. This skill objects will also be printed with both bendy and rigid materials. Lewis has spun off previous work on multi-material printers into an organization referred to as Voxel8, a beginning-up in Somerville, Massachusetts. Her multi-cloth printer might assist with the athletics put on that Voxel8 is constructing, says Lewis. Wearable contraptions need to be bendy around joints whereas also having inflexible parts to condominium electronics. Saiz calls the printer "pleasing work", including wistfully: "There's nothing like that for ceramics or steel."

And in March 2018, a group led with the aid of Jerry Qi, a materials engineer at Georgia Institute of technology in Atlanta, unveiled a 4-in-one printer. This combines a nozzle that extrudes molten polymer with one which prints gentle-delicate resin, ready to be cured via ultraviolet lamps or lasers, and two that print wires and circuitry from tiny dots of steel13. The print heads work collectively to make built-in devices with circuits embedded on a inflexible board or interior a flexible polymer enclosure. Qi says his group is now collaborating with electronics organizations drawn to printing circuit -board prototypes quicker than everyday methods.

It wasn't so simple as bolting 4 distinct printers into one platform: the researchers additionally mandatory to improve software that could permit each and every print head to speak with the others and preserve song of the development.

The container continues to be removed from offering on early visions of bringing mass manufacturing into people's homes. For now, refined printers are too costly to attraction to non-consultants. however 3D printing has come a protracted manner in the past two decades. Todd remembers individuals touring his lab in the early 2000s to look his method to fuse specks of metallic filth together to grow elements. in comparison with the conventional milling machines and metal-cutting programs in neighbouring labs, his 3D-printing machines struck guests as a complete oddity. "It became like we had been some type of a dog enjoying a piano in a bar," he recollects. Now, for a lot of organizations, that trick is standard observe.

No comments:

Post a Comment